User:Woodscooter/NewRMLHQ

Introduction

We currently have 50 sq.m of floor space and about 10 sq.m of loft storage space. We have found this supports a maximum attendance of 15 members in any evening. Roughly half that number are regular attendees and the others are committed members who come when they have something to do or when they are free to attend. Overall, the current membership is about 95 persons.

The Makerspace is limited in practice by its small size and in turn this limits its usefulness to the community. We would like to open more than one evening per week to make better use of our facilities, and to provide unsupervised access for established members.

RHP has promised to provide room for a new Makerspace in the re-development of Ham Close, and the Requirements section of this document gives a possible description of what is needed, for communication to the architects of the development.

It is unlikely that the new space will be provided to us fully-fitted. We will have to add furniture, shelving and storage space ourselves, at our expense. We will be responsible for the cost of electric power, broadband internet and water use.

We hope that we will not be expected to pay rent to RHP, or business rates to LBRUT. This would change the ethos of the Makerspace from a free community resource to a commercial venture, only available to those who can afford to pay for it.

If the Ham Youth Centre is being rebuilt, it's possible we will be housed in the same building.

Requirements

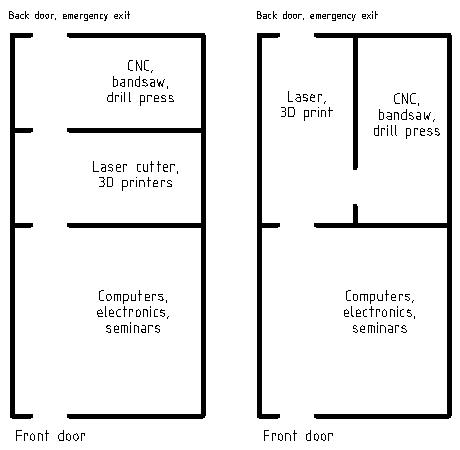

- Space: The new space must be a minimum of 100 sq.m, ideally would be 140 sq.m (1500 sq ft.) This space should be divided into three areas, with brick or block walls between them to provide noise isolation.

- 50% of the floorspace would be allocated to computers, electronics, assembly and faultfinding activities. The space could also be used for teaching and seminars.

- 25% of the space would be a room for the laser cutter, 3D printers and any future computer-controlled machines. There must be storage space for spooled and sheet materials and provision for an extractor fan.

- 25% of the space would be a room devoted to woodwork, metalwork, noisy and/or messy activities, including bench-top lathe, CNC mill, grinder, sander and bandsaw. There must be storage for sheet materials and provision for an extractor fan.

- The three main rooms would be joined with wide doorways. Having a corridor would be a waste of space. Here are alternative possible layouts.

- Outdoor space with electrical power would be useful. This could be shared with other community groups.

- Natural Light: Skylights should be considered. If windows are set into the walls, they should be at a high level because wall space provides a valuable area for fixing shelves and for anchoring fixed equipment. Electric light will provide all essential task lighting day and night.

- Utility: In addition to the three main rooms, we need an all-gender toilet with washbasin and one or two cubicles. Also an area with sink and drainer for making tea and coffee with space for a small fridge and storage for cups and plates.

- Telephone: Conduit for a telephone cable (for internet connection only) to one room.

- Electrical supply: Single phase, 10-way consumer unit. Each room to have one circuit for 13A socket outlets and one circuit for powering two wall-mounted 2kW fan heaters. One or two lighting circuits for the whole space.

- Gas supply: Gas pipework to be provided to one room, but not yet connected to the gas main. It's for adding gas central heating in the future, if necessary.