Ian M's Lathe Notes

Back to Ian M's profile

Currently these notes are semi-organized and non-authoritative. As I become more experienced with the RML CJ18A mini-lathe, I'm cleaning up, extending and reorganising them. Some lathe operating experience is assumed. If in doubt, *ASK* me, Jonathan H or another experienced minilathe operator!

* Andy H should be asked any questions involving RML usage policies or acquiring tooling or materials through RML.

Please do not use the lathe until you have received induction

The Lathe

Its a CJ18A Mini-Lathe from Amadeal.

Its a Chinese import 7x14 mini-lathe. The 7x14 refers to the maximum diameter and length of work, in inches and is only a theoretical measure of the working envelope as you lose length to the chuck + any tailstock tooling, and the diameter is over the bed, not the cross-slide. See actual specifications below.

Most if not all Chinese 7x10 to 7x16 mini-lathes seem to be remarkably similar (not uncommon with Chinese products due to Shanzhai (山寨) ) and the OEM of our Amadeal CJ18A Mini-Lathe was probably Yangzhou Realbull Machinery Co. Ltd. Very similar lathes are also made by Sieg, but their lathes tend to be slightly less sophisticated than the equivalent Realbull models.

N.B. Many Sieg parts are known to have slight but critical differences from Realbull parts, so DON'T order Sieg spares for a Realbull lathe!

Key Specifications

Amadeal says the CJ18A Mini-Lathe is a 7x14 model with:

- Power 550 W

- Distance between centres : 350 mm

- Swing Over Bed: 180 mm

- Swing Over Cross Slide: 110 mm

- Spindle Taper: MT3*

- Tailstock Taper: MT2

- Chuck diameter: 100 mm

- Spindle Speed: 50 - 2500 rpm (with digital readout)

- Spindle Bore: 20 mm

- Cross slide Travel: 65 mm

- Range of Metric Threads: 0.5 - 2.5mm.

- The lead screw is metric, pitch 1.5 mm.

- The spindle center is 90.6 mm above the flat of the bed (measured).

- The motor controller is FzDz model SCR800W, DC 0-200V, 6A

- The 550W motor is a PM brushed DC motor, nom. 180V, 3A

Even though the compound and cross slide handwheels appear to be calibrated in thousandths of an inch, as ours is a metric machine, they only approximate that. One turn of a slide handwheel is 1mm advance, and they have 40 divisions, so each division is 0.025 mm, (approx. 0.984 thou). Similarly, the tailstock quill advances 1.25 mm per handwheel turn, which has 50 division dial, giving the same 0.025 mm divisions, but only 4 turns per 5 mm. The carriage handwheel is awkward - it moves approx. 19.2 mm per turn, and doesn't have a dial scale.

* The spindle does not have a full length MT3 taper. Morse taper dimensions

Notable Accessories

We have:

- 160 mm (6 1/4") Faceplate

- 100 mm (4") three jaw self-centering chuck (OEM standard) 22.5mm bore, with inside and outside jaw sets

- 100 mm (4") four jaw (independent) chuck with reversible jaws (8 TPI screws)

- Tailstock drill chuck (max. 13 mm dia.)

- Live center for tailstock (+ OEM fixed center)

- Four way Tool Post (OEM Standard)

- Quick Change Tool Post + 3 tool holders

- Fixed Steady Rest

- Travelling Steady Rest

You'll find all of the above on the shelf above the lathe, with the accessories in the wooden box, apart from the steadies, which live next to it. Change gears, spare parts, and most cutting tool tips/blanks are in labelled white rectangular tins behind the lathe.

Measuring Tools

We have:

- Various dial indicators - the one with the adjustable magnetic base stand is the most convenient for most lathe setup work.

- 25mm micrometer (in little grey case)

- Grey case containing set of measurement tools including dial calipers, micrometer, steel rule (metric & inch), engineers square, and a fish-tail gauge

We currently lack

- A tool height setting gauge

Hand Tools

Some common tools needed for normal use are kept with the lathe, in or attached to the wooden accessories box:

- 2 mm Allen key - adjusting cross-slide and compound gibs

- 4 mm Allen key - quick change toolholder tool clamping screws + height adjust, tightening dials

- 5 mm Allen key - four way toolpost tool clamping screws, engaging/disengaging threading indicator

- 6 mm Allen key - locking/unlocking quick change toolholder

- 8 mm spanner - locking carriage when 8 mm socket can't be used, locking gib adjuster nuts

- 13 mm spanner - changing chucks, locking steady rest jaws

- Very long needle nose pliers - for grabbing swarf safely, holding one end of emery cloth safely so you can keep your fingers away from the jaws, and extricating small objects from awkward places.

Change Gears

See "Conquest Super Lathe" manual (below), section 4.7 Change Gears, PDF pages 28-29, but see below for mesh adjustment. The LittleMachineShop.com "Mini Lathe User’s Guide" (also below) section Threading gives a far better explanation, with pictures and diagrams, but its for a lathe with a US 1/16 inch pitch leadscrew, not a metric 1.5 mm pitch one like ours, so you *MUST* ignore all the tables in that section, replacing them with metric mini-lathe (with 1.5 mm pitch leadscrew) equivalents.

We have the following tooth count gears: 20,20, 30, 35, 40,40, 45, 50,50, 60,60, 80,80 which consist of the OEM power feed gears + the metric change gear set. Apart from the metal 20 tooth pinions, they are all plastic, probably Delrin if the molded in 'POM' marking can be trusted, but possibly plain Nylon 6, and are metric Module 1.

If we wanted to add the capability to cut US/Imperial threads we'd need to buy additional 55, 57 and 65 tooth gears, and possibly a 21 tooth metal pinion.

CGTK's Change Gear Calculator (link preloaded with our gear list) is useful if you don't want to calculate the ratios from first principles. Not all suggested combos will physically fit.

- Take care *NOT* to loose the keys in the A and D shaft keyways - turn each shaft till the keyway is up before removing the gear. They are 4 mm square, 8 mm long feather (rounded end) keys.

- The B and C gears are coupled by a hollow stub shaft (with an integral key), which is so tight in the gears it has to be pressed or driven out - I've made a puller just for this task, kept in the change gears tin.

- The center of the B-C stub shaft *MUST* be lubricated where it runs on its pin on the change gear banjo bracket, with grease or heavy oil. Seizure of the stub shaft due to running dry is a frequent cause of catastrophic mini-lathe geartrain failures!

- Don't get oil on the change gears as it can cause plastic gears to crack. Only PTFE drylube or plastic compatible white grease should be used on their teeth.

- Adjust the B-C pin position in the straight slot first to set the C to D gear mesh, tighten its nut, then swing the whole banjo about the D shaft boss to set the A to B mesh, and finally tighten the banjo clamping nut.

- Check both gear meshes have running clearance by turning the chuck by hand enough to complete one full turn of the leadscrew, and by attempting to turn the intermediate gear(s) to assess backlash, If excessive resistance is felt or if there's significant backlash, readjust the gears. If you have difficulty judging the mesh, a strip of 80 gsm copier paper (approx. 0.1 mm thick) wound into the meshing teeth before tightening the stud or banjo will give appropriate clearance once removed. Once setup, check the gears run quietly under power.

- If the sum of the tooth counts C+D is the same as for the ones you just removed and they were correctly meshed, you don't need to move the stub shaft pin. If A+B is also the same, you don't need to move the banjo. e.g. If it was set up for 16:1 reduction power feed, 1 mm (40:60 - 50:50) for M6 and 1.5 mm (e.g. 40:60:40) for M10 pitches can thus be achieved by only swapping gears.

The change gears, puller, etc. and a box spanner for the banjo nut are kept in a white rectangular tin behind the lathe.

Power Feed

When used for turning with power feed, the change gears should be set for a 16:1 reduction (A:20 : B:80 - C:20 : D:80) using the pair of small metal 20 tooth pinions and the 80 tooth plastic gears (largest in set), for a feed of 0.09375 mm per turn (1.5 mm/16). Unless continuing your threading project the next session, please re-fit the 16:1 power feed set after threading so the power feed is ready for use.

- *ALWAYS* leave the feed direction selector lever in its neutral (no feed) position, and the half-nuts open after use.

- *ALWAYS* check the carriage lock is disengaged before engaging power feed. Unlock the carriage after use.

Threading Dial

The threading dial is an aid to re-engaging the half-nuts at the right moment so the tool will retrace its previous path cutting deeper, rather than offsetting axially some fraction of the thread pitch and ruining your work. Its based on the concept of the lowest integer multiples of the leadscrew and thread (being cut) pitches that exactly match, but for mechanical simplicity it only covers certain selected multiples of the leadscrew pitch.

We have a choice of three pinion gears:

| Teeth | Colour Dot | Usable lines | OD gear | Dist. per turn |

|---|---|---|---|---|

| 14 | Red | 1,7 | 7.51 mm | 21 mm |

| 15 | Orange | 1,5,9 | 8.05 mm | 22.5 mm |

| 16 | Green | 1,4,7,10 | 8.37 mm | 24 mm (2 mm/div) |

They are now colour coded, with a paint dot on the gear end face (the only non-wear surface). The 16 tooth one is normally left on the lathe, but disengaged when not threading to minimise wear on the lead screw. The others are kept in the Change Gear tin.

There's a threading dial 'pickup' calculator here: https://www.cgtk.co.uk/metalwork/calculators/threaddialindicator

Initially select Lathe: Custom, and enter the following below:

- Units: Metric

- Lead Screw Pitch (mm): 1.5

- Thread Dial Indicator Gear Teeth: 16,15,14

- Lines on Thread Dial Indicator: 12

- Line Marking: Every Line Numbered

Note the teeth list is entered in reverse order so the resulting table highlights any required pinion changes.

N.B. The dial is only friction clamped to the pinion by its center screw. If you have any reason to suspect it may not be properly aligned:

- With the power off and the carriage unlocked, engage the feed direction lever upwards. You'll probably need to turn the chuck by hand to get it to engage.

- If the threading indicator isn't already engaged, loosen the threading dial support block bolt, pivot the block to engage the pinion with the leadscrew and retighten the bolt.

- Engage the half nuts, again turning the chuck by hand till they drop in.

- Turn the chuck a couple of turns, top towards you to take up any backlash, then lock the carriage, taking care not to push it left while locking it.

- Loosen the screw securing the dial to the pinion.

- Align the '1' line of the dial with the index line, by rotating the dial clockwise, then retighten the screw.

- Don't forget to disengage half-nuts and unlock the carriage!

The above instructions should result in the half-nuts engaging cleanly when exactly on any valid line when threading towards the headstock. If it is required to thread away from the headstock, there will be a slight offset from the line due to backlash between the spindle gear and leadscrew, so engage slightly early.

Changing the pinion:

- Loosen the threading dial support block bolt and disengage from the leadscrew.

- Undo dial center screw, and remove it and the dial, dropping the old pinion out the bottom.

- Oil the shaft of the new pinion with a drop of light oil and insert it from below, gear end down.

- Refit dial and screw.

- Check the dial and pinion turn freely with minimal resistance.

- Align as above.

Tailstock and Steadies

These are mostly used to support long work (long with respect to its diameter) to improve rigidity, increasing accuracy and reducing chatter. The Tailstock quill is also used with a drill chuck for drilling.

Tailstock

The tailstock can be offset to turn shallow tapers between centers. We don't currently have the accessories to turn between centers, namely a MT3 dead center for the spindle, or any drive dogs for the work. Also realigning the tailstock after turning a taper can be a PITA. The photo shows the tailstock adjusting screw locations (C - Lateral, and D - Skew) and the block on the baseplate they engage with. Adjustments can only take effect when the tailstock locking lever is eased to take the pressure off the baseplate. As we don't have a MT3 center, one has to turn a fresh point on a test workpiece for a rough tailstock alignment reference. Fine alignment, to avoid inadvertent taper turning, can be done by mounting a long precision ground bar between the chuck (or preferably a center in the spindle), and a dead center in the tailstock and sweeping it with a dial indicator on the carriage. Finally a test cut should be taken at either end of a bar between centers, and the diameters checked with a micrometer. Assuming the bed has previously been properly levelled and shimmed to take out twist (not the case at RML as we don't have it bolted down), any remaining difference in diameter will be double the tailstock offset, smaller at the tailstock being offset towards the front. Fine adjustment cant be achieved by jacking with the screws, its best to ease the adjusting screws, bump the tailstock into alignment then take up the screws again, checking the alignment is maintained when the tailstock is unlocked and relocked. There is no vertical adjustment, though shims can be added between the tailstock and its base.

Tailstock Quill

There is a metric/imperial scale on the top of the quill, read against the end of the tailstock, for depth measurement when drilling. The tailstock quill has a 1.25 mm pitch thread and a 50 division dial. Each division is therefore 0.025 mm, and it only takes 4 full turns of the handwheel to move the quill 5 mm.

To eject MT2 taper tooling and centers from the tailstock, wind the quill all the way in.

N.B. The quill anti-rotation pin (dog-tip setscrew + locking nut in top of tailstock near to the quill lock) is only M5. It will sheer if a large diameter drill jams in the work. Please back it out clear of its keyway if using large drills, and use alternative methods of preventing chuck rotation. To re-engage it, crank the quill out till you can see the keyway, align it with the screw and screw in the screw till it gently bottoms out, then back it off a quarter turn. Try twisting the quill to check its properly engaged, then tighten the locking nut gently to hold the screw in position clear of the bottom of the keyway.

Steady Rests

We have two, both with brass tips that must be kept lubricated during use.

The fixed steady mounts on the ways, and is most useful when turning longer work that wont fit through the spindle bore. Adjustment is critical, and the surface the tips run on must be smooth and concentric, as any misalignment that forces the work off center will result in the work wobbling in the chuck, marring it, with a high risk of it becoming un-chucked, which can be dangerous at speed.

The travelling steady mounts to the headstock side of the carriage to locally resist the deflection of thin long work, due to the cutting forces. It only has two tips, to resist climb, and deflection away from the tool, and requires readjustment after every cutting pass.

Tooling and Tool Holders

Key dimensional data:

- The quick change holders accept up to 10 mm shank tools.

- The four way toolpost has 50 mm long sides, a seat width of 15 mm and can clamp tools of up to 5/8" (15.875 mm) shank (check this), but the slot base is only 10.4 mm below the spindle center so cannot be used with >10 mm shank tooling unless it has a dropped tip. Large tooling with a centered tip is also problematic as you run out of height above the shank when trying to shim to match the spindle center height.

Quick Change Toolpost

The quick change toolpost and toolholders are setup for mostly easy use.

The three toolholders have cantilever height setting arms, with a height screw and knurled locking nut. You cant adjust the height by 'jacking' with the height screw due to its offset leverage. Instead, back off the height screw and hold the toolholder at the desired height while locking the dovetail clamp, then adjust the height screw (and locking nut) to hold it there, then check it doesn't change height significantly when you unclamp and re-clamp the dovetail. A HSS RH turning tool and a HSS hand-ground grooving/parting-off tool are kept mounted in two of the holders and set to height. The third is available for other tools, it *may* have a 90° point form tool mounted, for 45° chamfers.

The quick change toolpost has been modified with an internal spring to press the dovetail clamp outwards and help stop it twisting or flopping about to ease toolholder fitting and removal. The dovetail clamp (socket headed screw on toolpost side opposite dovetail) should go from open (with the toolholder lifting out or dropping in easily) to fully clamped in only half a turn. Wiggle the toolholder gently while clamping it to get a consistent height. If the dovetail clamp ever gets misaligned, twist it straight by eye, slacken off a bit further than usual to get a toolholder on, clamp it to align the dovetail then release, reseat the toolholder and re-clamp to ensure its at its preset height.

Unfortunately the OEM height setting screws on the toolholders foul the toolpost locking nut handle, so the toolholder must be removed to change toolposts. There is enough nut handle swing to allow the quick change toolpost to be unclamped and rotated to fine set the tool angle without removing the toolholder. It also seems the mating surfaces may be slightly out of square, as if you rotate the toolpost 90° or 180°, the nut swing may be insufficient to re-clamp it without removing the toolholder to do so. Add a M10 washer under the locking nut if the handle ends up pointing in an undesirable direction! A thin M10 washer is kept with the toolpost collar for this purpose, and will shift the handle position by about a third of a turn.

ToDo: Make a taller nut of a similar pattern, to clear the height setting screws.

Four Way Toolpost

The OEM four way toolpost is significantly more rigid than the quick change toolpost + holders because it has fewer and thicker parts and less overhang. Therefore the four way toolpost should be used when using carbide tooling. It requires shimming under the tool to set the tip height to the spindle center height - see below. The tool shanks are mostly significantly less than 15 mm wide, so need to be centered under its clamping screws, tempting as it is push the shank in for full side contact with the toolpost. If possible clamp the shank with all three screws not just two.

Shimming

We typically only mount up to two tools, and want maximum rigidity, so use 50 mm x 15 mm shims, (the full seat area), preferably with deburred edges and radiused corners so they aren't a hazard to the operator.

We have pre-cut and marked shims of the following thicknesses:

- 1x 3.23 mm, 2.42 mm, 1.56 mm, 0.32 mm, and 0.25 mm

- 2x 1.00 mm, 0.77 mm, 0.12 mm, 0.11 mm, 0.10 mm and 0.05 mm

- 4x 0.53 mm

Our shims are mostly found materials (hence the awkward thicknesses) and are mostly a mixture of aluminium and steel, with a couple of GRP ones. The toolpost seat must be absolutely clean to avoid embedding debris in the aluminium or GRP shims, to get a consistent height and avoid tilting the tool - wipe it every time you change a tool! Put the thin shims at the bottom of the stack to avoid the tool shank edges creasing them. Shims are kept in a little yellow plastic box with a clear lid, near the carbide tools case.

I made a tool height setting gauge (T shaped black acrylic with steps in its sides) which can be used to check the tool tip height matches the spindle center height using either the flat of the ways or the saddle as a reference. The tool tip should just fit under the lip of the appropriate step, with the T arms across the ways flats or on the saddle. It is kept in the box with the carbide insert tools.

ToDo:

- Cut more shims neatly, mark them with their thickness.

Do test cuts and start noting shim stack-ups for various tools.- Organise shim storage!

HSS Tools

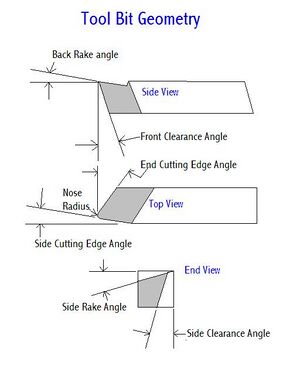

Our HSS tools are made from 8 mm square bar stock, hand-ground to tip profile in-house. See LittleMachineShop's Grinding Tool Bits notes.

I've installed our usual HSS LH turning and parting off tools in two of the quick change holders and set the heights correctly. There are a couple of other HSS tools or tool blanks knocking about. Taking heavy cuts turning steel (even with good cutting oil) blunts HSS tools fairly quickly, which are time-consuming to re-sharpen nicely without a dedicated tool & cutter grinder with appropriate jigs. Its worth noting that the usual 'speeds & feeds' tables are commonly based on surface speeds expected to give a half hour (active cutting) tool life before resharpening.

I touched up the LH turning tool by lapping on wet & dry (silicon carbide) paper on glass (Aka: 'Scary Sharp') working upwards through the grits 200, 400, 600 and finally 1000, initially 'bluing' the surfaces to be lapped with a marker pen to see which areas needed taking down more. The end of the tool was significantly uneven so I touched that up freehand on the bench grinder to flatten it when it became apparent that 200 grit lapping wasn't cutting where it needed to. There was an existing micro-bevel on the leading side, which I kept. Finally I 'dubbed' the leading corner vertical edge on the 1000 grit to give it a very slight nose radius. A test cut on brass gave a very nice finish when turning.

Ian B has purchased some spare 8mm HSS tool blanks - talk to a lathe trainer if your proposed lathe work needs custom ground HSS tooling.'

Brazed Tungsten Carbide Tools

Somewhat of a half-way house between hand ground HSS tooling and insert tooling with the disadvantages of both and some more besides - e.g. they are much harder to sharpen. So why do we bother? Some tool geometries would be awkward and tedious to hand grind, and Chinese import brazed carbide tooling is about half the price of similar HSS tooling, and far more readily available. Also, for space constrained tooling like boring bars, if you want carbide, for insert tooling, the size of the insert and its clamping seriously limits the minimum hole diameter you can work in. I have purchased a set of 3/8" shank brazed carbide tipped boring bars, but we currently cant sharpen them, due to lack of a diamond grinding wheel.

Tungsten Carbide Insert Tools

Decoding ISO insert tooling part numbers: https://www.cutwel.co.uk/blog/learn-the-turning-tool-iso-code-system

| PartNo | Description | Insert | Shank | Shank H/mm | Tip H/mm | Shim H/mm |

|---|---|---|---|---|---|---|

| SSKCR0610H06 | 75° through boring | SCMT06204 | Long | 6 | 6.34 | 4.33 |

| SSSCR0610H06 | 45° deep facing, internal chamfering | SCMT06204 | Long | 6 | 6.13 | 4.58 |

| SWUCR0610H05 | 93° boring, deep facing | WCMT050308 | Long | 6 | 6.22 | 4.48 |

| SWGCR0810E05 | 90° RH turning & facing | WCMT050308 | Short | 8 | 8.25 | 2.45 |

| SSSCR0610E06 | 45° turning, chamfering | SCMT06204 | Short | 8 | 8.75 | 1.93 |

| SSBCR0610E06 | 75° RH turning, chamfering | SCMT06204 | Short | 8 | 8.72 | 1.98 |

| LW0810R-04 | 60° external threading | JCL15-120 | Short | 8 | 7.44 * | 3.28 |

| QA0812R-03 | grooving, parting off | CK3 | Short | 8 | 8.23 | 2.5 ? |

| LN0813R-04 | 60° internal threading | JCL15-120 | Long | 7.95 | 7.44 * | 3.28 |

| PartNo | Description | Insert | Shank | Shank H/mm | Tip H/mm | Shim H/mm |

|---|---|---|---|---|---|---|

| QA0812R-03 | grooving, parting off | CK3 | Short | 8 | ~8.5 (not in use) | |

| Glanse SIR0012K11 | 60° internal threading bar | 11IRA60 | Long | 12 dia | ??? | ??? |

Shim stack heights in bold are tested, in italic are only calculated. Tip heights marked * are with new JCL15-120I inserts. The single remaining plain JCL15-120 insert has a slightly higher tip height.

Carbide tooling typically requires two to three times more speed than HSS and at least a couple of 'thou' depth of cut for best results.

Chatter can rapidly kill carbide tooling by chipping the cutting edge. To improve rigidity and reduce the risk of chatter, the cross-slide and compound gib screws need to be well adjusted so there is minimal play in the slides, tool stick-out should be minimised, the four way toolpost should be kept over the cross-slide, and the work should be kept close to the chuck (or otherwise supported by tailstock or steady rest) to avoid excessive deflection.

Thermal shock is almost instant death to carbide, and when dry cutting the insert tip can run very hot, so do not add extra cutting fluid manually during the cut. Pre-apply what you need, evenly, before starting the cut.

Parting off or facing to center is high risk - if the tool tip is even slightly below center or if tool or work deflection takes it below center, the work will tend to climb over the tool tip as the cut approaches center, breaking the insert. To avoid this, the tool should be shimmed slightly above center, sufficient to allow for work and tool deflection, and unless very close to the chuck, a steady should be used. Its often preferable to part to a couple of mm dia. remaining then stop and saw through the remainder, then clean up by facing. Parting off hollow parts is much lower risk.

Further investigation of the Tungsten carbide insert tool height situation is not encouraging - the so-called 'set' in question does not have a consistent tip height (see above table)! In a real set, the insert seats *should* be machined allowing for the insert thickness to bring all the cutting edges to the same height with respect to the shank underside. However if you place them tip to tip on a table its easy to see there is considerable height variation, so they need to be individually shimmed (or at best, one machined shim will only be right for two or three tools). At this time we don't have dedicated shim stacks for each tool.

A 2.42 mm thick shim brings the SWGCR0810E05 90° RH turning & facing tool almost exactly to center height, and good results were obtained turning 1" steel pipe. However facing 50mm steel bar stock to center found it to be slightly low, leaving a fractionally under 0.05 mm 'pip' so it needs another 0.03 mm to bring it fractionally above center. Fractionally too high is generally preferable to fractionally too low, due to tool deflection, so adding an 0.05 mm shim to the stack should produce optimum results.

Inserts

Ian B has purchased the spare inserts we needed in sets of five. He even was able to get the CK3 parting-off inserts which had been difficult to source!

Inserts used in above tool set:

- 3x SCMT06204 (square, indexable) https://www.rdgtools.co.uk/acatalog/SCMT-06-Carbide-Insert.html

- 2x WCMT050308 (triangular, indexable) https://www.rdgtools.co.uk/acatalog/WCMT-05-T3-08-5XTIP-8813.html

- 2x JCL15-120 (60 deg threading point) https://www.rdgtools.co.uk/acatalog/X5-JCL-15-120L-THREADING-TIPS-60-DEGREE--X5-TIP---23455.html

- CK3 (parting off) https://www.rdgtools.co.uk/acatalog/CK3-CARBIDE-TIPS---PARTING--BOX-OF-5PCS--9437.html

Inserts used in other tools:

- 1x CK3 (as above) also missing from spare parting off tool

- 1x 11IRA60 in Glanse threading bar + 1x spare

Drills

Various sizes of center drills are kept in a plastic bag next to the wooden accessories tray. There's also a small box of 2.5 mm center drills.

We have a set of 11 TiN coated HSS drill bits from 1.5 to 8 mm, (in a cylindrical plastic index box) for tailstock drilling of brass, aluminium and non-abrasive plastics. To keep them sharp enough for the precision work we expect from the lathe, please don't use them for steel or reinforced plastics, and don't borrow them for non-lathe use. Metric and US numbered/lettered general use HSS drill bits are kept in red and black metal index boxes next to the drill presses.

Using the Lathe

General

Making dimensioned parts is primarily done by touching off the tool tip on a reference surface (with the lathe stopped, turning the chuck by hand), zeroing the handwheel dial, then manually counting turns and divisions. When backing off the tool its best to do so by exactly one whole turn so you don't forget the previous dial position. Stopping and measuring the work before taking the final cuts is essential if high accuracy is required. I've changed out the dial setscrews for flat tip ones with a tiny slug of solder under them so the dials are now friction fit on their shafts. i.e. if you hold the handle firmly taking up the backlash in the direction of cut, you can zero the dial just by grabbing and twisting it.

Carriage movement is less easy to measure as the handwheel is uncalibrated and advances an awkward bit over 19.2 mm per turn. Your options here when shoulders or other features must be exactly positioned are, in order of increasing accuracy:

- Use measuring instruments, scribe the work at the desired length then work to the scribed line. Its often convenient to black the work with a permanent marker, then scribe with the tool tip, turning the chuck by hand.

- for short distances, lock the carriage and use the compound, set parallel to the work

- Set up a long travel dial indicator to measure carriage motion.

N.B. with the leadscrew stopped, and the threading dial engaged, with its default 16 tooth gear, it will make one turn for every 24 mm of carriage movement (2 mm/div). This isn't accurate enough for positioning but is sufficient to check you aren't out by a whole mm or more.

Do not allow any solvents to contact the chuck guard clear plastic as it will make the plastic brittle, or even craze it, and try to avoid melting it with the work light!

Speeds & Feeds

The surface speed of the tool relative to the work (or visa versa) is important, and best results will be achieved when it is in a tool type and material specific range. Because the surface speed is proportional to the diameter and the spindle RPM, it is usual to vary the spindle speed in inverse proportion to the diameter to get the surface speed in the desired range, and keep it there as the tool tip moves closer to the spindle axis.

A cutting speed chart for HSS tooling, published by Model Engineer magazine can be found [here]. The second row is the target feed rate and the rest of the chart, apart from the diameter column is RPM.

For carbide tooling cutting iron and steels, recommended speeds are generally three times higher than for HSS, but the CJ18A 2500 RPM max. spindle speed (in high gear) means you can only reach the optimum speed range for over 15 mm dia work. For small diameter work, HSS tooling may well be a better choice.

An online metric speeds calculator is here: https://www.cgtk.co.uk/metalwork/calculators/cuttingspeeds

How to do the maths to calculate speeds and feeds: https://www.cutwel.co.uk/blog/speeds-feeds-made-easy

I've computed a table of max. cutting speeds for our lathe: CJ18A Cutting Speeds.pdf

If you can hear the lathe 'sing' as it cuts, you are getting chatter, which invariably results in poor surface finish. Try decreasing (or possibly increasing) the spindle speed till the resonance stops.

Once you have a wavy surface due to chatter, a light cut wont clean it up as the tool 'twangs' from peak to peak. You have to take a deep enough cut to get under it. For precision parts, its therefore desirable to take a trial finish cut while still 0.5 mm or so oversize, to give an opportunity to tweak the cut to get a good finish, check for taper, and that the part wont be undersize (on your test finish cut nominal diameter).

Slide Locks

- The carriage can be locked to the ways using the M5 hex screw through the top of the saddle to the left of the cross-slide. Double check the leadscrew is disengaged and the half-nuts open before locking it. Lock it when facing.

- The cross slide can be locked by a M4 socket headed cap screw just in front of its middle gib screw. Locking the cross slide is helpful when turning very shallow conical features where the cross slide handle is in the way of the compound.

- The compound slide can be locked by a M4 socket headed cap screw in line with the edge of the toolpost mount on the side with the gib adjustment screws. In normal use it should be kept backed off half a turn but it is desirable to tighten it for parting off operations to keep the resulting end faces flat.

Compound

The compound consists of a locking swivel and a top slide allowing cuts to be made at an angle to the axis e.g to produce bevelled or tapered features. There is a difference between US and UK usage, in the US a compound angle of 0° means the compound slide is parallel to the cross slide, but in the UK, 0° is parallel to the ways. The compound angle indicator on the CJ18A follows UK practice, 0° parallel to the ways, but it is not to be trusted, its out by a few degrees!

One of the deficiencies of the CJ18A lathe is the difficulty of setting the compound angle. It is held and locked by two screws hidden under the top half of the compound slide, which must be wound back till its toolpost end is clear of the pivot point to access them. This may have to be repeated several times to snug them up enough to tap it to the desired angle, then finally tighten them.

We generally keep the compound slide set approximately parallel to the ways so it can be used for short-distance longitudinal positioning without measuring. However it is unlikely to be closely parallel unless a test bar has been swept with a dial indicator on the slide, or test cuts made on a large OD workpiece and checked for taper.

Chucks and Chuck Jaws

Terminology

- Inside jaws have steps on the outside to grip the ID of hollow work, but can also be used as outside jaws on small diameter parts (i.e. that fit through the spindle).

- Outside jaws have steps on the inside to grip the OD of the work.

- Universal chucks have a scroll plate with a spiral screw thread that moves all the jaws.

- Independent chucks have individual adjusting screws for each jaw.

The Chucks

- The three jaw universal chuck can only grip near round or hexagonal work, which it centers, but its concentricity is not perfect so e.g. if you reverse the work and continue turning at the same diameter from the other end, you will see a line where the turned surfaces meet. It has separate sets of inside and outside jaws, and we normally keep the inside set installed to use as outside jaws for small diameter work.

- Our jaws are individually numbered, stamped in the groove. They must be fitted in the correct sequence. The jaw slots are not clearly marked. Lowest runout for small dia. parts is achieved if you fit the jaws with #1 anticlockwise of the makers mark, then continue anticlockwise for #2 and #3.

- A large strong rubber band is a great help getting all the jaws started on the scroll together - with slots #1 and #3 above the centerline and the scroll thread outer tip between #1 and #3, insert jaws #1 and #2 and put the rubber band round them to keep them in their slots. Insert jaw #3 and stretch the rubber band over it to hold it up into its slot. If the scroll was positioned correctly, all jaws should be at the same initial radius. The jaws can now be cranked in with the chuck key and they should all engage in step so they meet in the middle.

- Mini-lathe.com have the best instructions for changing the jaws.

- The four independent jaw chuck can grip most roundish or squarish work, which can either be carefully centered by the user, or deliberately gripped off-center.

- Its jaws are reversible so can be swapped from inside to outside by simply cranking each jaw out and reinserting it the other way round, one at a time. DON'T move the jaws to different slots as they are likely to bind.

- When setting up to face the sides of rectangular objects held crossways, it may be helpful to use both inside and outside jaw orientations, in symmetrical opposing pairs.

- Its screws move their jaw 1/8" (3.125 mm) per turn

- The jaws must never protrude from the chuck OD by more than one step, and for safety, its preferable they don't protrude at all, as they make the gap between the front of the bed and the chuck body an even more unforgiving meat grinder, and as the number of teeth engaged with the scroll or screw decreases, they loose strength, just when you need it the most to grip larger/heavier work.

Neither chuck is well suited to gripping tapered work safely. When seating work that doesn't quite fit through the chuck bore (which is larger than the 20mm spindle bore limit), be careful that it isn't seating on the chamfered edge of the chuck bore as it is far to easy to get the work slightly cocked so it doesn't run true.

Changing Chucks

- When changing chucks, use the small grey plastic mat to protect the ways under the jaws in case you drop the chuck.

- The spindle nose has two patterns of holes - the three hole pattern is for the three jaw chuck and the faceplate, and the four hole pattern is for the four jaw chuck. One hole is shared between the patterns, and is marked on the spindle nose.

- To fit a chuck:

- First check that the spindle nose and chuck back and recess are free of swarf, grit or other debris. Any foreign objects will tilt the chuck causing excessive runout and may mar the surfaces.

- Remove the nuts and split lock washers from its studs, line its studs up with the hole pattern (preferably with the stud nearest anticlockwise to the makers mark through the marked spindle hole), fit and hold it in place with your right hand, and with your left, get the lock washer and nut on the top stud, and take up the slack.

- One one nut is on, you no longer have to worry about dropping it, and can work round fitting the remaining washers and nuts, taking up the slack on each as you fit it.

- Next, work round again getting them all finger tight, then tighten them gently, and finally work round fully tightening them.

- Removal is the reverse of refitting. Put the washers and nuts back on the chuck's studs so they don't get lost.

Gripping Threaded Work

It is generally undesirable to chuck work gripped on a screw thread, as it is difficult to hold the work securely and get good concentricity while avoiding crushing the thread crests. However, if one must, one of the better ways of doing so is to wind a wire helix to fit the thread then clamp on the outside of the wire so it seats on the flanks of the thread. The wire should be mild steel or soft iron for steel parts and copper for aluminium and brass parts, single strand, round and of uniform diameter a little less than the thread pitch. It can be wound on the lathe, in reverse, by chucking a sacrificial mandrel of the same diameter and thread pitch, hooking the end of the wire round or under the jaw, against the direction of rotation, then holding the other end of the wire under tension with pliers and starting the lathe dead slow. Once wound and removed from the mandrel, the ends must be trimmed then it should be screwed on to the threaded work to provide a surface to chuck on.

Faceplate Work

Faceplate work is probably the most dangerous operation you can (or rather should) perform on a lathe. The working area is a large diameter spinning surface with protruding clamps to fixture the part that it is impractical to guard. Protruding clamps, studs, nuts etc. are very difficult to see at speed.

Treat the faceplate with great respect and caution if you wish to continue to be able to count to ten on your fingers!

The 65 mm cross-slide travel vs the 80 mm faceplate radius is a serious limitation that may require creative compound, toolpost and tool setups for larger parts, and doing full face cuts in two sections.

It is common practice to skim the faceplate to ensure it runs true. We have not (yet) done this, and wont till the spindle is in better bearings and the nose reground to minimise runout.

Clamping

Open ended/sided clamps should be oriented so that cutting forces drive the work towards the clamping bolt/stud, not out from under the clamp. Minimize the protruding length of thread past the clamping nut, if necessary using sacrificial bolts or studs you can cut to length, or even using a long M8 stud for one of the faceplate mountings, so you can get a clamp nearer to the faceplate center. Double-check all clamps are secure, manually turn the faceplate to check the work and clamps clear the ways, top-slide and toolpost, and stand out of the 'line of fire' (a disc extending from the faceplate) when spinning up the work for the first time.

If you need to machine close to a clamp, consider marking a safe limit circle on the faceplate and work with a marker pen to make it easier to see how close the cutting tool is to crash disaster.

I strongly advise reading chapter two of Tubal Cain's book "Workholding in the Lathe" several times before your first faceplate setup, and if possible get another experienced lathe user to check your first few setups before spinning them up.

Chuck Guard Removal

The faceplate is too large diameter to fit under the chuck guard, but the guard has an interlock switch wqhich must be closed for the lathe to run. The guard is now fitted with wing nuts so it can be removed allowing the the interlock switch to close when using the faceplate. It *SHOULD* *ALWAYS* be refitted if a chuck is fitted, except when turning work too large to clear the guard.

The chuck guard is primarily there to make it very difficult to start the lathe without removing the chuck key and to reduce the area of large diameter spinning surface exposed. It may slow down the projectile if a chuck sheds a jaw but is unlikely to stop it. Also it serves to contain coolant spray spun off the chuck. As we don't use flood coolant this usually isn't an issue for us. As setting up for faceplate work doesn't use a chuck key, and the most hazardous zone is the face of the faceplate, with its spinning projecting clamps, with full access required for machining operations, which a guard would not cover, the consensus is that removing the guard is an acceptable risk.

Turning and Facing

We are getting good results in aluminium, brass, and even steel using HSS cutting tools in quick-change tool holders, and the ~ 94 um/turn power feed. Unfortunately due to lack of rigidity in both the machine and smaller diameter parts, if you don't want the outer end to be over diameter, a light final cut and multiple 'spring' passes will probably be required.

For aluminium, a sharp HSS tool and 0.5 mm (20 div) depth of cut gives good results with power feed for rapid stock removal. Its also easy maths as each cut takes ~ 1 mm off the diameter. Finish cuts should be much finer, 0.1 mm (4 div) is 'in the ballpark'.

For steel, using carbide insert tooling, a 0.25 mm (10 div) depth of cut is more appropriate, and with pre-applied cutting oil, gives reasonable results with power feed if you use enough speed. The maths is not quite so easy as you are only taking 0.5 mm off the diameter per pass. Again, use finer finish cuts but try to plan your cuts so the final cut is still cutting, not smearing the surface!

When facing or parting off, some skill is required to turn the cross-slide handwheel steadily to get a decent finish and to avoid shock-loading the tool tip. Increasing the spindle speed in one or more steps to keep up with the reducing diameter is advisable, but avoid speeds that cause resonances (resulting in chatter). When parting off, small through-hole parts may be caught on a thin rod chucked in the tailstock, and pre-positioned inside the work with its tip right up to the parting off position.

Using the Steady Rests

For the fixed steady rest, see Blondihacks' Lathe Skills #26 - How To Use a Steady Rest! {below}

Ours doesn't have ball bearing fingers, so a smooth surface on the work and adequate lubrication are essential. The thumbscrews can only tighten the fingers, so for small adjustments outwards you need to either slack off the clamping nuts or ease them slightly and use a drift against the back of the finger's slot. Once set, check the chuck still turns freely.

The traveling steady rest needs to run on a machined surface, so at least for the first pass, must follow the tool, so its difficult to avoid using more compound slide overhang than is desirable. An initial surface should be cut next to the chuck or tailstock center before fitting the steady rest.

Both are a PITA to fit - the fixed one has to have its clamping post inserted up through the bed, and the supplied spanner is useless near the headstock, and the travelling one's mounting holes on the saddle almost invariably need swarf picked out of them.

Turning Between Centers

Using a MT3 to MT2 reducing sleeve, the MT2 dead center can be fitted in the spindle. Currently the MT3 spindle taper is compromised. Alternatively, a soft center can be turned immediately before use in the three jaw chuck, but that must have its 60° point re-cut to concentric if the chuck is disturbed, and needs to be either large enough to bear on the chuck body, or must have a lip to bear on the end face of the jaws to take the axial thrust. Recutting the center is a PITA, as the compound angle must be set to 30° anticlockwise, then reset to a true 0° afterwards. Maybe a right-hand 30° end angle zero rake form tool is the answer, or use the carbide insert tool SSKCR0610H06 as a form tool with the toolpost rotated 15° anticlockwise.

With the MT2 live center in the tailstock quill, this gives us a center either end of the work to hold it.

We also need a drive dog similar to this, and the corresponding drive post to bolt to the spindle nose. I have some 25mm bore thick wall iron pipe, which should do nicely. Lengths of the dog's straight tail and of the post TBD after I check how much the center protrudes. N.B. its recommended to tie the tail to the post to keep them in contact so they don't slam. Currently we will need to drive from the chuck jaws. Possibly use the exterior jaws with a short soft center gripped on the inside end and drive from the highest step.

Drilling

Always start with a center drill so deflection of longer bits doesn't start the hole off-center. For larger bits (> 5 mm), first drill to the web size, then to final diameter. For a precision hole, drill slightly undersize and ream to final diameter. Supply your own reamers!

Caution: See note about the quill anti-rotation pin in section Tailstock Quill above.

Boring

Caution: As the spindle doesn't extend right through the headstock housing, if boring in a through hole, chips tend to fall out the back and tumble in the spindle bore till they fall into the change gears. To avoid this, one should plug the spindle bore with a wad of paper towel or rag and when cleaning up afterwards, use a rod to push it through towards the tailstock, with the chuck jaws (if fitted) wound clear of the spindle bore.

A swivel bladed hole deburring tool (pale blue handle) can be found in the main room on the windowsill behind the drill press.

A couple of boring jobs have been bodged with an awkwardly angled turning tool and achieving acceptable effective rake with enough clearance to reach deep enough into the hole has been problematic. I reviewed the tools we had and found none suitable for starting out in a 13mm bore, the max diameter we can (easily) drill. I therefore decided to buy a set of boring bars and make a holder for them. I had difficulty finding anything affordable under 10mm shank - the best low cost option was a set of nine 3/8" (9.525 mm) shank brazed carbide tipped boring bars, which would be close to the max capacity of the quick change boring bar holder - if we had one! Unfortunately this holder for our specific toolpost is difficult to find except in a toolpost bundle. Another annoyance is the variable tip height of the set, varying from 1.8 mm to 2.8 mm above the center of the shank.

I therefore decided to make a boring bar holder of the Littlemachineshop.com (USA) style for use in the four way toolpost, as the additional rigidity will certainly help. Starting with a slightly over 50 mm length of 16 mm aluminium square bar and using the four jaw chuck , both ends were faced and an attempt was made to find its center and center drill it. It was then drilled out to ~9.8 mm after much drama due to blunt drills and drills that cut ~1mm oversize. Too big, but beggars cant be choosers as we didn't have a boring bar holder or a 3/8" reamer. Unfortunately the final hole ended up significantly off center. It was then chucked crossways and ~1 mm skimmed off its thickest side to gain clearance to allow it to be shimmed to height, then one side was slit lengthwise manually with a hacksaw.

It was fitted to the for way toolpost and loaded with a booring bar, which clamped firmly. A 0.86 mm shim stack brought the tip of the largest boring bar almost spot on center height, with the difference easily accommodated by twisting the tool slightly. The three jaw chuck was then remounted, and a piece of iron pipe chucked for a test. It cuts well and leaves a decent surface finish.

The boring bar setup is a work in progress - talk to me before attempting to use them if you have a project that would benefit from boring..

ToDo: Get something that can sharpen tools tipped with this grade of carbide - it needs some sort of diamond (or possibly CBN) wheel as green grit silicon carbide does little more than polish it. N.B. diamond wheels are rapidly eroded by grinding steel, so the supporting steel seat must be undercut with a regular grinding wheel before the diamond wheel can contact it.

We'll also need 50 mm square sheet shims to fit under the toolpost to gain clearance in the toolpost above the tool or toolholder. A 2.4 mm shim would give us about the same above and below spindle center height, and we probably need a small selection of thinner ones.

16/4/2024 - 23/4/2024: Made an aluminium 2.45mm under toolpost shim, to help make a new boring bar holder, this time not oversize. Started by facing ends of 166mm square aluminium stock to 50mm length. Then mounted it cross-wise in the four jaw chuck to flycut (face) ~0.3mm off one side so it fits in the toolpost. Shimmed the whole toolpost + 2.45mm, mounted the work face down and got it parallel to the ways. With a center drill in the 3 jaw chuck, found the edge and moved in 8mm to centerline of part and drilled it. Switched to 5 mm drill and drilled through - nasty long stringy chips. Drilled it out to 8mm then 9mm. Unfortunately the toolpost rigidity wasn't good enough for the blunt larger drills and the hole went a bit off-center laterally. I made a 3/8" D reamer with the end tapered to a slightly over 9mm pilot to fit, and chucked the part in the four jaw and reamed to size. Good fit on boring bar shanks. Slit with a hacksaw and deburred the slit.

ToDo: Make a 3/8 plug for back of holder to support it against the clamping screw pressure.

Thread Cutting

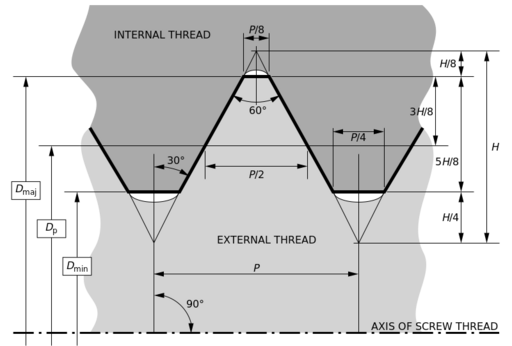

The objective is to cut a thread that complies with the ISO metric thread profile. Our lathe is not currently equipped to cut non-metric threads, (with the exception of BA which have pitches based on metric threads of that era).

Metric thread data - See 'Preferred Sizes' at: https://en.wikipedia.org/wiki/ISO_metric_screw_thread

See "Mini Lathe User’s Guide" section Threading for general techniques *ONLY*, and above for change gears and threading dial setup.

Amadeal specify the max. thread pitch as 2.5 mm. Any thread pitch greater than 1.5 nn requires the change gears to gear up. When gearing up it is desirable to distribute the ratio as evenly as possible over the two pairs of gears in the geartrain to avoid excessive tooth loading, with the larger driven gear (if different) on the D shaft.

External Threading

Initially turn work to required Major Diameter, set up change gears and threading tool, touch off on the work, zero the top and cross slide dials, and do a 'scratch' pass to check the pitch. Back off the tool using the cross slide, return the carriage, and re-engage the half nuts on a valid dial line clear of the end of the thread then immediately stop the lathe, and hand turn the chuck till the tool tip is (hopefully) over the scratch to check the thread pickup. If all is good, return the carriage again, restart the lathe, bring the tool back in and start cutting your thread.

Methods of doing so vary depending on the size of the thread and toughness of the metal, but straight-in plunge cutting is generally to be avoided as has the highest cutting forces, and does not reliably keep the carriage (and top-slide if set parallel to the work) loaded to avoid pitch errors due to backlash. It is common practice to set the compound angle so the cross slide is nearly parallel to the trailing flank of the threading tool tip, so all the cutting action is at the tip and leading edge. The angle should be fractionally steeper so the trailing flank rubs slightly to avoid deflection. The desired angle is slightly less that half the fishtail gauge nose, and can be set using the side of the nose and a near centerline from the tip to the tail offset slightly in the notch at the root of the tail V to reduce the angle slightly. Use a side notch on the fishtail gauge, held against the work, to set the tip exactly straight in to the work.

After each pass, back the tool out using the cross slide, return the carriage to the start and bring the tool back in to exactly the same cross slide position, before advancing the compound by the depth of the next cut. The depth of cut must decrease as the thread depth increases as the width of the cut increases proportionately to the total depth, which would otherwise result in excessive cutting forces.

If leaving the half-nuts engaged and reversing the lathe to return to the start of the thread for the next pass, its absolutely essential to back the tool out of the thread for the return pass as it will not follow the path of the cutting pass due to backlash in the geartrain, leadscrew mounts and half-nuts.

Internal Threading

Something I'm working on as the large Draper drill press needs a custom left hand thread nut for its spindle pully.

Cutting fluids

Why bother?

Watch this video and contemplate what's actually happening to that thin ribbon of metal being removed. Most of the lathe's motor power is being turned into heat by internal friction in the chip being removed in the zone around the cutting edge, and surface friction at, and immediately behind the cutting edge, near-instantly heating the chip by up to several hundred degrees. Reducing the surface friction using a suitable cutting oil reduces the strain on the machine as a whole, and reduces workpiece and tool heating (and thus expansion) with consequent improvements in maximum usable feed and depth of cut, surface finish and accuracy. It also drastically increases the life of the cutting edge.

Practicalities

We don't have a coolant system for the lathe and *really* don't want the maintenance hassles of using soluble cutting oil/coolant as if used infrequently its a PITA to keep recirculated high water content cutting fluids from going rancid and stinky, and they can also rust the ways, so even a total loss gravity feed system is problematic. Therefore if dry machining doesn't give a good enough finish, we tend to use oil applied topically, by hand to the work.

- Hard brass is typically free-turning without oil, however some light oil for the final cut can improve surface finish, but with the disadvantage that it will increase loose chip buildup on the tool as hard brass typically forms short spalls or splinters rather than curly chips.

- Many Aluminium alloys tend to be gummy, and Paraffin or other mineral spirits mixed with a little oil can help prevent the aluminum welding to the tool edge. WD40 will do at a pinch, but its messy to apply from a spray can.

- Steel really needs *GOOD* cutting oil. Lard oil is the traditional choice for steel. If there are any objections to lard oil, we should bite the bullet and get some commercial dark high Sulphur cutting oil, but beware, many such oils use an additive package that includes lard oil.

- Cast iron (except ductile) should be cut dry, as the carbon micro-inclusions self-lubricate it, and the carbide in the dust (primarily Cementite) are very abrasive, so tend to form a grinding compound if mixed with oil.

I've sorted out an oil pot lid with a 1/2" brass collar soldered in to give a nice smooth sided hole, for ease of use and to minimize the risk of spills when using a brush to apply cutting oils, and got some dirt-cheap brushes. It fits Shippam's paste (and similar own-brand spread) jars and I've found several jars and ordinary lids to seal them for storage. Unfortunately it isn't the easiest to get this type of jars' lids back on square so they seal properly, and if you over-tighten them and there's a temperature change, they can be a total <expletive> to reopen. Using the rubberised handles of a large pair of pliers to grip the jar lid just above its rim is the best option, and avoids damaging the lids.

N.B. For the smaller brushes, the glue holding the bristles in is attacked by paraffin. To prevent loss of bristles, crimp the aluminium ferrule of each new brush of this type before use.

We have, in labelled jars:

- Sulphurised Lard oil thinned with paraffin. Best choice for heavy cuts and threading in steel but stinky.

- Lard oil thinned with paraffin. Good for steel and acceptable for softer copper alloys

- Paraffin with a trace of light oil. Good for aluminium, and can help prevent squealing chatter on finish cuts in brass.

I've also got some paraffin wax (in the form of a stubby candle), which can be applied lightly (under power) to brass and aluminium stock especially on the finish pass. It makes less mess than oil but unfortunately tends to build up on the tool tip, making it difficult to 'work by eye' without frequent pauses to clean the tool tip.

We've also got a tin of Rocol RTD cutting compound, which is a thick paste. Its highly recommended for drilling and tapping steel (in the drill press or by hand), but as a paste, is less useful for general lathe work unless thinned to a fluid consistency, e.g. with paraffin or white spirits. OTOH its certainly worth trying for high speed facing steel as it is less likely to get flung off.

Cleaning and Maintenance

Swarf is a significant cut hazard to the operator, especially stringy swarf from cutting steel. Never touch it bare-handed - always use a tool e.g. a brush, or a hook, or needle nose pliers for grabbing long swarf.

- After use, brush all swarf off the toolholder, compound and cross slide etc. ways and leadscrew, brushing towards the rear to avoid sweeping chips under the carriage. Ian B has blocked off the opening at the headstock end of the rear splashguard (to try to keep swarf out of the motor), so one must sweep the swarf towards the open tailstock end and catch it in the metal dustpan. Preferably, also thoroughly clean out the chip tray under the lathe, but at least sweep out visible swarf.

- Wipe up any cutting fluid residue and re-lubricate affected sliding surfaces with way oil.

- Do not solvent clean the chuck guard, as it will make the plastic brittle, or even craze it. Water with a little detergent is permissible for cleaning it, with the guard totally removed from the lathe.

Before engaging the half-nuts for power feed/threading, check the leadscrew is clean! Best cleaned under power, with a toothbrush.

Caution: The traverse gears behind the carriage handwheel are in an open-backed housing and tend to become packed with swarf! Swarf buildup here will result in jerky carriage movement. Clean out as much as you can with a toothbrush ...

Lack of lubrication and/or swarf or dirt build-up can be disastrous

- If using the change gears/power feed, lack of lubrication of the B-C stub shaft center pin or either leadscrew end bearing can result in seizure and immediate destruction of one or more gears in the gear train or worse.

- Small pieces of swarf can get between the saddle and ways, or into the slides degrading accuracy, possibly permanently if hard swarf scores them, or jamming them. The carriage handwheel gears behind the apron are notorious for accumulating swarf, and swarf buildup on the leadscrew can prevent the half-nuts engaging properly, resulting in scrapped work, and possibly stripped half-nuts.

- Metal swarf can get into the motor (though Ian B has modified the rear chip catcher to reduce the risk) or into the control box via the leadscrew, and short-circuit stuff. At best it will blow the fuse and need a strip-down to clean it out, at worst it may require a replacement speed controller (currently £96) and/or motor (currently £105) and possibly other electrical parts. We have fitted a 3D printed insert round the lead screw to fill most of the U notch in the control box to keep swarf out, as it tends to drop onto the 'Filter' board which is mounted horizontally, below the leadscrew.

- Grit from grinding, sanding etc. forms a grinding paste with the way oil, and will rapidly wear out the ways, saddle and slides. Keep grit off at all costs e.g. by covering the ways and slides during grinding/sanding operations, and if there's any chance grit has gotten where it shouldn't, clean and re-lubricate *BEFORE* moving the carriage or slides, then move the carriage and slides, wipe down where they were with a clean paper towel and check there's no remaining traces of dirt other than clean way oil on the paper towel. If it doesn't come clean when you re-lubricate and move it again, a full strip down may be required to solvent clean and relubricate the precision sliding surfaces.

- Although a metalworking lathe *can* be used to turn hardwood, wood dust and small chips are extremely pernicious, as they get everywhere, even clinging to clean surfaces, are abrasive due to their silica content, and are hygroscopic, promoting rust. An even more thorough clean-up than after using abrasives is needed, immediately afterwards. Oily wood dust and fine wood chips in significant quantities are a fire hazard, even in the trash bin.

Lubrication

See section: "Lubrication" in LittleMachineShop.com "Mini Lathe User’s Guide" (below). As we usually only open two nights a week, in the table on page 16, Daily lubrication becomes Weekly and Weekly becomes Monthly.

General Maintenance

- The grubscrews holding the cross-slide and compound slide dials tend to loosen due to vibration and use of the dials. Keep them snugged up, but not so tight the dials cant be set without an Allen key.

- The screws holding the cross-slide nut tend to work loose due to vibration. Crank the handle to and fro through the backlash and visually check there is no movement of the screw heads in their holes. If there is, see the notes below.

Removing and Refitting the Carriage

Its possible to remove the carriage from the bed for cleaning etc. without dismantling it. The only stop to its motion is the righthand leadscrew bearing.

Start by removing the tailstock. Crank the carriage to the tailstock end then remove the leadscrew pillow block (two screws and a Nyloc nut on the leadscrew end). With the half-nuts open, hold the leadscrew centred in them and crank the carriage off the end of its rack, then slide it off the end of the bed.

Refitting is the reverse of removal, except (if its gibs are correctly adjusted) the carriage will be very tight on the end of the bed ways so may be difficult to work onto the ways without a stack of blocks of wood or similar to support it at exactly the right height. See below for refitting the tailstock end leadscrew pillow block.

If the Apron has been off, refit it with the screws no more than lightly finger tight and only finally tighten them after checking lead screw engagement at both ends of the carriage travel and that the rack and pinion operates smoothly over the full travel.

Removing and Refitting the leadscrew

The leadscrew is nom. 16mm dia, turned down at the ends for the plain unlined pillow block bearings that support it, at the headstock end, turned down further and keyed for the D gear, and at the tailstock end, threaded for a Nyloc nut to adjust its end float.

To remove it, you must remove the gear, key and nut and one of the pillow blocks, which are secured by two screws into the bed. If possible, to retain a height and alignment reference to ease refitting, do not disturb one of the pillow blocks. With the half nuts open it may now be slid out of the remaining pillow block, and out of the carriage. Support it at the carriage as you slide it to try to avoid it scraping the half nuts.

When refitting the leadscrew, if both pillow blocks have been removed, find its balance point, fit it through the half nuts and firmly close them to support it at the balance point. The pillow blocks may then be refitted but with their screws only finger tight, checking the leadscrew is parallel to the ways, not tilted. The carriage should then be moved as close as possible to one of the pillow blocks, the half nuts reengaged, and that pillow block's screws loosened then tightened so it takes up alignment from the leadscrew, then this is repeated for the other pillow block, and again for the first, which iteratively improves the alignment.

If only one pillow block has been removed, you can skip directly to supporting that end of the leadscrew with the half nuts while fitting the pillow block and tightening its screws. If the apron has been off the carriage, more iterations are required, as the apron screws must be loosened when initially fitting the pillow blocks so they sit flat against the bed, then the pillow blocks and apron screws tightened finger tight, then the apron screws should be snugged up, then each pillow block loosened and tightened with the screw next to it supported in the half nuts, and the apron should be realigned and tightened as above.

Finally check that leadscrew turns freely with the half nuts open and no D gear fitted, then refit the tailstock end Nyloc nut, tighten it then back it off slightly till the leadscrew turns freely again. Don't forget to oil the pillow blocks!

Issues and Annoyances

As of April 2024 - mostly resolved, apart from the spindle bearings and resulting runout, the lathe is in better condition than it has been for a number of years.

Inhibit circuit fault

Fixed 25/04/2024: The speed potentiometer/switch has been replaced. The old one's plastic rotor had distorted and did not reliably operate the switch mechanism, which tended to jam on, disabling the inhibit function. The pot was also responsible for the motor stuttering issue last autumn, so was overdue for replacement. Note that the switch operates opposite to that of a normal switched 'volume' pot so the OEM pot is probably the best option. Available from https://www.amadeal.co.uk/acatalog/Potentiometer-AMA_SP_CJ18_157.html @£16 inc P&P.

19/3/2024: During initial investigation of the fault, swarf contamination on the speed controller board blew the two MUR1660 rectifier diodes that form the negative side of the SCR controlled bridge rectifier that feeds the motor. The lathe was down for a month while I investigated, waited for spares and finally fitted and tested them. We now have a set of spare diodes in stock in case they ever get blown again, and I've added Kapton tape over the legs of the TO-220 package diodes and SCRs to reduce the risk of swarf shorting them.

01/10/2024: Also added a 3D printed bushing round the lead screw to fill the U slot in the right side of the control box and exclude swarf. To fit it one has to remove the left lead screw bearing, the D change gear, and the change gear banjo carrying the C/D stub shaft

The inhibit circuit's function is to prevent the lathe starting at high speed by forcing you to reduce the speed knob to zero before the motor will start. It is currently defective allowing the motor to be started at a high speed. Our KBIC clone speed controller does not have an inhibit function, so it is handled by the braking relay on the 'filter' board, which is supposed to only latch in the 'run' position when you close the speed control's inhibit switch by turning the knob fully anticlockwise.

Four Jaw Chuck has two jaws too tight

Fixed 27/10/2023: Two of the chuck jaws were tight in their slots, making precise adjustment difficult due to lack of 'feel'. Moving the jaws round the slots showed the problem mostly followed the jaw not the slot. The grooves in the opposite sides of the affected jaws that run in the chuck slots were slightly out of true, and the rails either side of the slots were slightly too thick towards the center. Due to the difficulty of seeing the high spots, after cleaning up and deburring the jaws didn't do enough to ease them, I decided to grind the top of the rails where they were binding. Several repetitions of spotting with Engineer's blue, grinding, then diamond filing the high spots has eased them enough. I cleaned everything, greased the jaw slides and screws, and refitted the studs so the chuck is now fit for service.

N.B. Don't move the jaws to a different slot - the formerly tight jaws *must* stay in the slots furthest from the makers mark.

Excessive Runout

Mostly fixed 24/10/2022, Q3 2023: I ground the chuck seating surface of the spindle nose (outside lip) to under half a thou runout. This also cleaned up several burrs. It would be possible to do better, but that would need good spindle bearings, and a more rigid toolpost grinder mount. Q3 2023: Found the spindle nose seating face was uneven. Improved by grinding.

Our spindle nose was damaged years ago by a person with little mechanical aptitude (who shall remain nameless) beating it up with a hammer mushrooming the spindle nose. We are getting several thousandths runout at the end of the MT3 bore, a MT3 to MT2 reducer sleeve in it runs visibly out of true, as does the spindle nose flange. When you put a chuck on it, the runout is magnified by the distance from the spindle nose. Ideally we would replace the spindle when we change the bearings but its £52 from Amadeal and money is tight. It may well require more work after the bearing upgrade. Once good bearings are in, if we can borrow a decent MT3 arbour as a reference, we should consider skimming the bore.

Spindle bearings

- The spindle bearings appear to be close to worn out. They are notably noisy when running, and there appears to be more slop in the spindle than is desirable. There is notable resonance around 600 RPM, and surface finish of end faces is often poor. We have some ideas for possible replacement/upgrade, but it requires a major teardown.

- The original bearings are allegedly 6206-2RS or 6206-ZZ deep groove ball bearings - 2RS codes rubber seals both sides and ZZ codes metal shields. Although the deep groove gives reasonable ability to withstand axial loads, the bearing balls point contact means they are vulnerable to brinelling due to shock loading. The jammed on three jaw chuck didn't help this, as before we skimmed the spindle nose lip, it had to be driven off using a bar through the spindle bore, shock loading the bearings every time. Also even a minor 'crash' could have brinelled them due to eccentric shock loading, and the lathe has previously been crashed badly enough to need drive gear replacement. There are also issues with the 'approved' method of spindle and bearing removal from the headstock brinelling them, even if you don't abuse the spindle nose with a hammer!

- A possible replacement is 30206 tapered roller bearings. The new bearings are slightly thicker so the plastic spindle spacer (15) needs to be machined to length to get the 45 tooth spur gear that drives the change gears laterally aligned with the tumbler gears. If a temporary replacement (3D printed?) is fitted, the lathe can be run (without power feed capability) so this can be done on the lathe after fitting the new bearings. As tapered roller bearings have line contact, they are significantly more resistant to brinelling.

- See Talk:Ian_M's_Lathe_Notes for notes, links etc. for this upgrade.

Motor stuttering

- Fixed 25/04/2024 by speed pot replacement. 21/09/2023: The motor was running very erratically and it was very difficult to set a speed. Several loose connections were found in the control box, mostly loose female spades to the motor controller board, but also a dry jointed braking resistor on the 'Filter' board, and an inhibit wire completely off its terminal on the forward/reverse switch, making intermittent contact. After tightening and/or remaking all affected connections, it was much improved but still not right below 300 RPM. The remaining issues were due to poor wiper contact in the speed control pot, and stripping it, cleaning the track and contact ring and re-tensioning the contacts resulted in the motor now running smoothly over the full speed range. The speed is slow to settle, and while part of that is probably the lag in the digital tach, I suspect that the KBIC motor speed controller isn't properly tuned as it was (allegedly) previously replaced.

Drive belt slipping

- Fixed 28/9/2022: During testing the motor after the above issue, it was noted that the chuck could be stalled, slipping the drive belt, with not much torque. The drive belt was determined to be loose and a bit worn, but still in acceptable condition.

- Access for servicing the belt requires removing the control box (2 spades to ZVR switch disconnect the supply, speed sensor and motor simply unplug from the 'filter board'), the motor cover, chuck guard switch assembly + wiring cover, the change gear 'A' (drive) shaft carrier assembly, and the tumbler gear assembly. See https://youtu.be/EkxlIz01BdA for disassembly/reassembly, though on our lathe, the speed encoder ring on the spindle prevents the belt cover from being fully removed without disturbing the spindle nuts. There is enough room to work with it loose, but still trapped by the encoder ring. Also, unlike the video, if the 'jack' screws under the headstock are correctly adjusted, and the studs aren't excessively bent, there is no need to make custom studs.

- It turns out that our lathe was missing the M6 hex headed jack screws that press the motor down to resist the belt tension, and the motor had cocked out of position at a severe angle. I know Ian B had had considerable trouble adjusting it after the motor fault back in October 2022, and I believe it had been getting slowly worse ever since. The jack screws were probably mistaken for headstock fixing bolts during disassembly after the crash that resulted in the metal Hi/Lo gears being fitted, then lost. The penny washers on the studs had dished, so I turned them over and backed them up with smaller washers and switched to Nyloc nuts so they cant back off due to vibration. N.B. There is a packing washer on the motor side on one of the studs, presumably so the shaft is true to the ways. Adjusting the motor is awkward to say the least. One has to slack the stud nuts off a lot, pry under its rear end to lift it enough to be parallel to the ways, snug the stud nuts, check alignment, then set the jack screws and their lock nuts to hold it there, and finally tighten the stud nuts.

- Tension: According to Sieg, it should be possible to twist the belt 90° mid span with a light finger grip. Other sources say 1/32" - 3/32" deflection mid span with light finger pressure.

Speed display blanking

- The speed display has been intermittent, blanking and flashing 8888 and 0 at certain speeds for as long as I have been using the lathe. Finally on 18/07/2022 it failed completely, with no display. I removed the display module and bench tested it - the pins are labelled 5V GND PL PE, PE is frame ground and PL is a TTL level pulse from the speed sensor - confirming that it was in good working order. My suspicions then turned to its power supply on the 'Filter' board. With both the sensor and display unplugged, the 5V rail was found to have a only a couple of volts, but the unreg DC was 17V and stable. Replacing the 78L05 5V regulator restored the 5V rail and normal operation.

- I conclude its been failing for a while with high load current due to speeds with more lit segments causing it to drop out, resetting the speed display, causing it to blank, lowering the current enough for the regulator to recover, then the display MCU lamp tests (8888) then re-acquires the speed, repeating ad-nauseum till the speed is changed. I don't like the design as the high input voltage results in excessive dissipation.

- ToDo: If it fails again, bench test display to measure its worst case current consumption, then fit an appropriate dropper resistor to reduce the 78L05 dissipation.

Quill spinning when drilling

- The quill was tending to spin while drilling because its anti-rotation pin (a M5 dog tip setscrew) was sheered. I've removed the debris, aligned the scale with the top of the tailstock and fitted a longer M5 dog-tip setscrew to replace it, with a nut to lock it at the correct height. N.B. the pin isn't that 'meaty' so if using big drills in tough metals, to prevent shearing it, it should be backed out so the quill can be turned by hand and unwanted rotation controlled by being quick with the quill lock if it starts to spin, or even using a close fitting rod in one of the chuck key holes with plastic tube over it to protect the ways.

- If the screw sheers again, the quill will need to be removed and the tailstock taken off the lathe so the sheered tip can be shaken out, and if the setscrew is difficult to remove it probably means the threads are mangled where it sheered. Try driving it right through with the quill out.

Sloppy quick change toolpost locking mechanism