Talk:Ian M's Lathe Notes

IanM (talk) 07:59, 1 June 2023 (UTC) Comments, corrections and feedback from other RML lathe users and/or experienced machinists are welcome.

Control Box

FzDz SCR800W Speed Control board

The negative side of the SCR controlled bridge uses MUR1660 dual common cathode diodes, which when the board is mounted are at the right side of the box, facing up on the heatsink so can blow due to swarf ingress via the leadscrew hole, and did so March 2024. No other damage occurred. After replacing the diodes, the board is OK. I covered all the power TO-220 legs where they are flat on the PCB next to the heatsink with Kapton tape to reduce the risk of small swarf shorting them again. Larger swarf is still a problem as it could short tab to tab on the heatsink.

We have three spare diodes + a pack of silpads in stock (Lathe spares tin).

https://services.ts.com.tw/storage/resources/datasheet/MUR1620CT%20SERIES_I2104.pdf

ToDo: Identify the SCRs. Order some 1 1/4" 8A fast fuses - we have 10A fitted

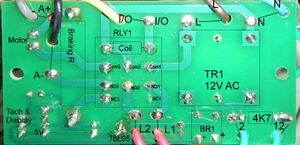

'Filter' board

This board has nothing to do with mains filtering. It carries the transformer for the tacho display's 5v supply, the braking/inhibit relay, the braking resistor and an extra 4.7K resistor nominally used to reduce the speed when running in reverse, but the speed control board doesn't have that facility so the function is disabled and one of the green wires is hanked up and not connected.

Theory of operation

The relay switches power (Line and Neutral) to the speed controller when activated. It also disconnects the braking resistor from the motor, and connects the speed controller DC output (via the reversing switch). Its coil power is tapped from its switched AC, so it latches on, but passes through a contact pair in the reversing switch so it drops out if the switch is moved to O (off) to prevent 'plug' reversing. Performing a fast (braked) stop using the reversing switch is not advisable as its contacts will break the DC motor circuit under load, which they are not rated for. Initial coil power is supplied via the inhibit switch of the speed control, only when it is fully anticlockwise (zero speed). Interrupting power to (or by) the ZVR switch (E-stop) also causes the relay to drop out, braking the motor.

The relay is Clion HHC68B-3Z, 220V AC coil 3PDT. See https://static.chipdip.ru/lib/399/DOC001399886.pdf page 7. One pin is cropped.

N.B. The wires from the front edge of the board (top of photo) must be routed via the left notch in the speed controller board heatsink, to allow it to fit far enough into its mounting slot for the relay to clear the leadscrew.

Reversing switch

Is a Kedu ZH-A Drum Switch.

I'm still figuring out the wiring. So far I have:

- 2 Black

- 5 Black

- 6 Black

- 7 Grey - Filter A+

- 9 Red (x2)

- 10 Yellow - Filter I/O

- 11 Green

- 12 Green - Filter 12 ?

https://sys2sell.de/mediafiles/PDF/ZH-A%20(3).pdf (English page 2)

ToDo: Trace all the black and red wires.

Speed Potentiometer

4.7K linear with an unusual switch used for inhibiting starting at speed, ON at the fully anticlockwise 'off' position. 1/4" D shaft.

Its on its last legs, with the pot starting to go intermitant and a failed inhibit switch.

Fuseholder

The incoming Live feed from the ZVR switch is next to the panel. This is an unsafe condition.

ToDo: Swap its connections!

Notes for spindle roller bearing upgrade

- http://mikesworkshop.weebly.com/headstock-upgrade.html - blog of this upgrade on a very similar lathe

- https://youtu.be/HYOgmhpBUJs - Video of upgrade on minilathe without Hi/Lo gear with discussion of setting the taper roller preload

- https://www.arceurotrade.co.uk/projects/C3_BC/C3-bearing-change.html - Step by step guide on a Sieg C3

- https://groups.io/g/7x12MiniLathe/topic/mini_lathe_spindle_tapered/82278520 - discussion of lubrication issues post-upgrade

- https://www.mini-lathe.com/Mini_lathe/Tuning/headstock/headstock.htm - disassembly *without* a puller. Note the use of a rawhide mallet. Our spindle is already marred by someone beating on it with a hammer :(

When we get around to this, it would be worth replacing the two rear socket headed cap screws holding the headstock to the bed with hex headed machine screws, so future headstock maintenance can be performed without removing the motor.

IanM (talk) 09:10, 17 October 2023 (UTC)

Concept for a boring bar holder

We need the capability to use small boring bars <10mm shank. The main problem at small sizes is rigidity, so it is probably desirable to avoid the QC toolholder. The 4 way toolpost can clamp 16mm but the slot base is 10.4 mm below center height, leaving only 5.6mm above, not enough for a 10mm toolholder.

Raising the whole toolpost 2.5mm (ideally 2.4mm) would be a game-changer, giving 7.9mm below and 8.1mm above center height allowing a block clamped directly in the toolpost to be bored for up to 1/2" (12.5mm) shank tooling. After boring, slit one side of the block for clamping, so it flexes when the toolpost clamping screws are tightened, clamping the round tool shank. Littlemachineshop.com (USA) sell a 1/2" boring bar holder of this style but it would be uneconomic to import.

To bore it, first drill slightly under diameter with the drill bit in the 3 jaw chuck, then use the 4 jaw chuck to hold a boring bar with the desired offset.

2.5mm Aluminium sheet is probably the best choice to raise the toolpost - cut 50mm square ?? and drilled for the center stud. The boring bar holder is probably best made of 16mm aluminium square bar.

Update: Bought a set of 9 3/8" shank boring bars. The shanks are 9.45mm and tip heights are around 2.4mm above center with some outliers +/- 0.2 mm. Therefore after boring the holder block 9.5mm (test drill an ally offcut 9.5mm and see how close to shank size it is, but I bet it will need boring), with the 2.5mm shim under the toolpost, remove the shim, and touch up the tips to correct relief and rake with the bar rotate to bring the point to a thou or so above center. Worst case I may need to file the top of the holder block to allow it to be shimmed up a few thou.

IanM (talk) 16:11, 29 July 2023 (UTC)

Lathe dog and drive pin

Needed for turning between centers. See https://littlemachineshop.com/products/product_view.php?ProductID=4464 for the general style I propose.

Scaling from the photos, the M8 drive pin is 60mm long, threaded for half its length. The quick & dirty option here is cut down a M8 x70mm or x80mm hex headed bolt and round its end.

The smallest (10mm capacity) dog has a 41.5 mm x 7 mm tail, and a M5 screw. The 20mm capacity dog has a 32.5 mm x 11 mm tail and a M8 screw. 30mm is similar but with a 35mm tail. I have an offcut of 25mm bore heavy pipe, that should be suitable for stock in the range 15mm to 25mm.

A Counterbalance weight is commonly fitted to the spindle nose hole opposite the drive pin. ToDo: calculate balance weight

IanM (talk) 03:59, 31 July 2023 (UTC)

Fine Feed

A 3D printed set of cojoined 80/15 tooth (for the BC shaft) and 90 tooth gears can increase the reduction ration from the standard 16:1 to 24:1 giving a 0.0625 mm fine feed. Although they can be bought from LittleMachineShop: https://littlemachineshop.com/products/product_view.php?ProductID=1137 I think we can print them ourselves in ABS and am working on OpenSCAD models for them. The C-D reduction can possibly be improved with a 14T pinion driving a 91T gear on D, which gives 26:1 and 0.0577 mm feed. IanM (talk) 12:19, 17 October 2023 (UTC)

Other desirable mods

- https://gadgetbuilder.com/ThreadingTools.html#AutoStop - Auto-disengage for the half-nuts.

- Can we do this better? Possibly a V groove in an actuator pin through a block to lift a ball bearing in a cross hole in the block to push a strong spring round the half-nut lever base off a catch pin. Engaging the half-nuts cocks the spring, which is then held with no force on the lever till it trips.

- N.B. GadgetBuilder had a crash due to the half-nuts failing to disengage under load. It may need a backup electrical trip via a heavy duty relay to interrupt power to the ZVR stop/start switch, or maybe retrofit a 5 pin ZVR switch so the electrical trip only has to interrupt the coil current. It may also be possible to use the motor controller's low current inhibit circuit, though for safety, it would need to latch till the speed knob inhibit switch closes or power is cycled.

- On further consideration, an electromechanical trip may be preferable to the mechanical one, triggering a 'brute force' solenoid to disengage the half nuts, as continued over-travel if the trip fails could then stop the motor. IanM (talk) 12:09, 17 October 2023 (UTC)

- https://www.youtube.com/watch?v=_PuSl_PyMNI - Copper soft jaws from water pipe

- Set for the 3 jaw chuck completed 10/10/2023.

- ToDo: Make a set for the 4 jaw chuck.

Spares/Accessories for consideration

Arceurotrade https://www.arceurotrade.co.uk/Catalogue/Machine-Spares/C2-Mini-Lathe-Spares/C2-180A-Potentiometer-with-Switch - Right value and switch type, but has splined 6mm shaft. £10.64 https://www.arceurotrade.co.uk/Catalogue/Machine-Spares/C3-Mini-Lathe-Spares/C3-256-Leadscrew-Grommet-Dustproof-Cover - Leadscrew shaped grommet to exclude swarf, £3.35

The drive belt is a modulus timing belt, 1.5x70 That's 1.5*PI (~4.712 mm) pitch, 70 tooth, so approx 329.8 mm long. According to Amadeal its nom. 9.8 mm wide, but the motor pully endcap has been shimmed to allow a slightly wider belt and a standard 10 mm one will fit.

Old: Grinding spindle nose to fix 3 jaw chuck seating

I made a proposal to resolve the chuck seating issue (Telegram message to Ian B):

On further thinking about the misfitting three jaw chuck, neither the four jaw chuck nor the faceplate require that precise alignment, as one always adjusts the work held by/on them to run true, so a tiny increase in their runout when mounted will be insignificant.

As a replacement spindle is only £52 but a replacement 4" three jaw chuck is £120, the lowest risk cure for our excessively tight fitting chuck would be to turn down the register (outer) diameter of the lip (inner ring) of the spindle nose till the three jaw chuck just fits cleanly.

As there's very little to be taken off, setting up a Dremel in a 3D printed adapter for toolpost grinding is probably the best approach.

Ian B concurred:

I'm in full agreement with your suggestion, to grind the lip of the spindle.

Changing chucks should be easily done and having to whack the three jaw chuck to remove it can't be good for a lightweight lathe like ours.

And you're saying the grinding bit of a Dremel will be adequate for the spindle? Perfect.

TLDR: We have fixed it!