Facilities: Difference between revisions

Beardedfool (talk | contribs) |

|||

| (19 intermediate revisions by 2 users not shown) | |||

| Line 52: | Line 52: | ||

''Please do not use the laser cutter until you have received induction'' | ''Please do not use the laser cutter until you have received induction'' | ||

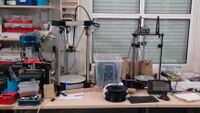

===3D printing=== | ===3D printing=== | ||

We have several 3D printers that can be used to print downloaded models or rapidly prototype your designs. | |||

Some basics on 3D printing [[3dprinting-basics|here]] | |||

Our Printers: | |||

====Flashforge adventurer 3==== | |||

[https://www.flashforge.com/product-detail/flashforge-adventurer-3-3d-printer Flashforge's page ] | |||

====Prusa I3 ==== | |||

Genuine Prusa, on permanent loan from Leo. controlled by a Pi running Octoprint. | |||

Its so new to us, best ask Leo how to use it! | |||

====Geeetech I3 pro B==== | |||

[[Geetech_I3_Pro_B| here]] | |||

[[File: 3DPrinter.jpg |200px|right | 3D printer]] | [[File: 3DPrinter.jpg |200px|right | 3D printer]] | ||

<!-- | <!-- | ||

NB this is all commented out but I want to keep the text as we still have some of the machines | |||

====Zombie Printer==== | |||

A machine so modified it got a new name | |||

* Dedicated page [[The_Zombie_Printer|here]] | |||

====BIQU Magician==== | ====BIQU Magician==== | ||

* A good machine as an introduction to 3D printers for new-comers. Works well with minimal changes of settings. More here | * A good machine as an introduction to 3D printers for new-comers. Works well with minimal changes of settings. More here | ||

| Line 66: | Line 86: | ||

** pi | ** pi | ||

** deltamaker | ** deltamaker | ||

====Geetech Dual Extruder==== | ====Geetech Dual Extruder==== | ||

Currently only one extruder working | Currently only one extruder working | ||

| Line 82: | Line 95: | ||

Web GUI, IP is shown when machine is started. Has a slicer built in | Web GUI, IP is shown when machine is started. Has a slicer built in | ||

--> | --> | ||

===CNC Machines=== | ===CNC Machines=== | ||

====CNC Mill==== | ====CNC Mill==== | ||

| Line 107: | Line 121: | ||

=Crafts= | =Crafts= | ||

===Sewing machine=== | ===Sewing machine=== | ||

There is a | There is a are 2 sewing machines from John Lewis on loan from Andres and AndyH but neither are currently working as of Feb 2025, sorry, on the list but the list is long | ||

Feel free to use when ever. It is kept in its box on the gray shelves next to the kitchen. | |||

Follow this video for [https://www.youtube.com/watch?v=eFABAbK4Beo threading] and first steps! <br clear=all> | Follow this video for [https://www.youtube.com/watch?v=eFABAbK4Beo threading] and first steps! <br clear=all> | ||

| Line 113: | Line 129: | ||

[[File:Electronics Bench 2022.jpeg |200px|right |Electronics Bench]] | [[File:Electronics Bench 2022.jpeg |200px|right |Electronics Bench]] | ||

[[File:20221206 Electronics.jpg|200px|right |Electronics Bench in use]] | [[File:20221206 Electronics.jpg|200px|right |Electronics Bench in use]] | ||

Our electronics area contains various test equipment, tools and supplies to help repair and build various electrical/electronic items. Most notably, we have a four channel digital oscilloscope, a dual 30V 2A bench PSU, two Fluke digital multimeters + various cheap ones, a temperature controlled soldering station, and desoldering/rework stations as well. | |||

See our [[Electronics]] page for a more comprehensive list of equipment, notes, tutorial links, etc. | |||

=Makers Equipment= | =Makers Equipment= | ||

| Line 184: | Line 142: | ||

=Engineering/ Woodwork= | =Engineering/ Woodwork= | ||

===Bench drill=== | ===Bench drill press=== | ||

*Silverline 262212 Drill press | *Silverline 262212 Drill press | ||

**Chuck Capacity 13mm | **Chuck Capacity 13mm | ||

| Line 192: | Line 150: | ||

<br clear=all> | <br clear=all> | ||

===Lathe=== | ===Metalworking Lathe=== | ||

[[File: Lathe2.jpg |200px|right | Lathe]] | [[File: Lathe2.jpg |200px|right | Lathe]] | ||

In the kitchen. | In the kitchen. | ||

Its a CJ18A Mini-Lathe from [[https://www.amadeal.co.uk/ Amadeal]] | |||

[[https://web.archive.org/web/20170618065028/http://www.amadeal.co.uk/acatalog/CJ18%20Manual.pdf Manual]] | * [[https://web.archive.org/web/20170618065028/http://www.amadeal.co.uk/acatalog/CJ18%20Manual.pdf Manual]] | ||

* [[Media:Lathe InductionNotes.pdf| Induction Document]] | |||

''Please do not use the lathe until you have received induction'' | |||

'' | '''Attention all lathe users:''' | ||

Make sure the speed is set to zero (knob fully anti-clockwise) before pressing the green start button. Except in an emergency, stop the lathe with the speed knob before pressing E-stop or opening the chuck guard. | |||

NEVER operate the reversing switch when the lathe is running. | |||

[[User:IanM|IanM]] has written some more detailed [[Ian M's Lathe Notes|notes on using the RML Lathe]]. | [[User:IanM|IanM]] has written some more detailed [[Ian M's Lathe Notes|notes on using the RML Lathe]], Contact him on Telegram to book training/induction. | ||

===Bandsaw=== | ===Bandsaw=== | ||

| Line 296: | Line 254: | ||

=Other facilities= | =Other facilities= | ||

===The Round Table=== | |||

Possible our most important area; a place where people have a cup of tea, chat or do some work | |||

===Bathroom=== | ===Bathroom=== | ||

Yes we have one of those. Wheel chair accessible. | Yes we have one of those. Wheel chair accessible. | ||

Latest revision as of 14:32, 27 February 2025

Audio Visual

Bluetooth-enabled Stereo

How to use

- Turn on the power switch connected to the stereo to the right of the double-doors.

- Press "VIDEO/AUX" on the stereo input dial (in the middle) to connect it to the Bluetooth receiver.

- On your Bluetooth-enabled smartphone or laptop device, go into your Bluetooth preferences and search for devices. You will see "Belkin HD" as one of the available devices. Pair it with your device and start playing music/podcasts/Internet streams.

- If you do not see "Belkin HD" then power cycle the Belkin device and search again.

CAD - Computer aided design

Laser cutter

Privately owned Laser cutter (60W) can be used periodically for prototyping.

Please do not use the laser cutter until you have received induction

3D printing

We have several 3D printers that can be used to print downloaded models or rapidly prototype your designs.

Some basics on 3D printing here

Our Printers:

Flashforge adventurer 3

Prusa I3

Genuine Prusa, on permanent loan from Leo. controlled by a Pi running Octoprint. Its so new to us, best ask Leo how to use it!

Geeetech I3 pro B

CNC Machines

CNC Mill

N.B. This is currently not operational

CNC Mill - OpenBuilds C-Beam CNC Router In the cloakroom

Please do not use the CNC Mill until you have received induction

- Instructions on use from Leo here and Nick here (Internet Archive)

CNC Metal Mill

N.B. This is not yet operational

Denford MicroMill

CNC Lathe

Denford MicroMill N.B. This is not yet operational

Denford Microturn

Crafts

Sewing machine

There is a are 2 sewing machines from John Lewis on loan from Andres and AndyH but neither are currently working as of Feb 2025, sorry, on the list but the list is long

Feel free to use when ever. It is kept in its box on the gray shelves next to the kitchen.

Follow this video for threading and first steps!

Electronics workbench

Our electronics area contains various test equipment, tools and supplies to help repair and build various electrical/electronic items. Most notably, we have a four channel digital oscilloscope, a dual 30V 2A bench PSU, two Fluke digital multimeters + various cheap ones, a temperature controlled soldering station, and desoldering/rework stations as well.

See our Electronics page for a more comprehensive list of equipment, notes, tutorial links, etc.

Makers Equipment

- Arduino Starter kit

- Funduino kit with loads of sensors

- Raspberry Pi (with Pi Camera)

Engineering/ Woodwork

Bench drill press

- Silverline 262212 Drill press

- Chuck Capacity 13mm

- 350W

See our Drill press page for general instructions and its Manual for specifics.

Metalworking Lathe

In the kitchen.

Its a CJ18A Mini-Lathe from [Amadeal]

Please do not use the lathe until you have received induction

Attention all lathe users: Make sure the speed is set to zero (knob fully anti-clockwise) before pressing the green start button. Except in an emergency, stop the lathe with the speed knob before pressing E-stop or opening the chuck guard. NEVER operate the reversing switch when the lathe is running.

IanM has written some more detailed notes on using the RML Lathe, Contact him on Telegram to book training/induction.

Bandsaw

N B This is out of action and in need of replacement

- Nutool HBS230 230mm Two Wheel Bandsaw

- 230W

- Similar Manual

- Replacement parts:

- Got some tyres from [www.Solenttools.co.uk solent tools]

- Ian got a new blade from ???

Jigsaw

Bosch PST 700E 500W Jigsaw Manual

Mitresaw

Erbauer ERB255GS 2000W 10" Sliding compound mitre saw with laser

Router (handheld)

Black & Decker KW850E 1100W

here Manual

Planer (handheld)

Ryobi EPN-6082 600W

Manual

Bench Grinder

Clarke Metalworker CBG 6RZ

Manual

Belt Sander

N.B. We no longer have this as the motor broke. Kept as a reminder we need one and for safety warning

- KOBE KBE2714140K

- Manual and here

- Safety: Please don't use the dust extraction when sanding metal - hot sparks, wood chippings and lots of air equals fire

Compressor

Mains-powered air compressor with a long air pipe and a few tools, including paint sprayer.

- Ratchet tap handles

- 0 - 10 BA tap & die set (imperial)

- Broken bolt extractor set (Easy Outs)

General purpose

- Ultrasonic cleaner (6.5L) - Tank internal dimension: 300 (L) x 150 (D) x 150 (H) mm

- Small screw driver set with prying tool for mobile phone disassembly

- Spanner set 6mm to 26mm - In cloakroom, on bathroom door

- Hot glue gun

- Dremel 200 rotary Multi-Tool (two speed - 15K/35K RPM no load) - Instructions

- Flexible shaft

- 3rd party sets of bits and accessories

- The green box bits & accessories set is the most complete. The other one is overspill + half worn-out bits. The flexible shaft is now kept off the tool as its rarely used. Please try not to loose the little shaft coupling nut from the tool end of the flexible shaft! The Dremel and its attachments and accessories live in the large translucent plastic crate on the grey shelves next to the cloakroom door.

- RS Pro Mini Drill - 12V drill (max. 17K RPM no load) & Variable speed PSU

- with 3.2 mm (1/8") capacity 3 jaw chuck

- uses Dremel bits, but not fixed accessories

- Lives with the Dremel in the large translucent plastic crate on the grey shelves next to the cloakroom door. Chuck key is taped to its 12V power cord. A better choice than the Dremel for precision drilling.

- Set of files (round, square, triangular, flat, half round) - On side wall next to Woodworking bench

- TORX screwdriver set - behind Electronics bench, opposite Woodworking

- Hex key set - Metric & Imperial/US, boxed - behind Electronics bench, opposite Woodworking

- Hacksaws: Junior (6") and full size (12") - Hanging up behind the Woodworking bench

- A full size hacksaw is an effective means to cut metal from 3 mm to over 50 mm thickness. Also useful for hard plastics.

- Our Amtech 12" hacksaw needs four full turns after taking up the slack to tension the blade. Spare 12" 18 TPI and 24 TPI blades are hanging with the hacksaws. The spare 6" blades are in the spare drills box on the power-tool shelves the other side of the window.

- There's more to using a hacksaw than you might think - incorrect blade tension or wrong choice of blade for work thickness, can ruin a blade in minutes and make your job much harder and slower. See How to use a Hacksaw - a 26 m video series covering basics, cutting straight, and how to cut thin metal without damaging the blade - by 'Course You Can' (Jim Garratty).

Equipment and Tool Defect List

Stuff that's usually available, but is currently broken, (or recently fixed) should be on our Equipment and Tool Defect List.

This is not a 'live' defect list, and tools/equipment may fail unexpectedly between its update and your intended visit.

Computers

Printers and Scanners

Desktop computers

- Windows PC in the office/Laser Cutter room. See Laserpc

- 2 Linux PCs under 3D Printing bench

- All-in-one Apple Mac next to Electronics bench,

- Other

- Hard drive duplication station [[1]]

- SIM card cutter (micro and nano)

- Assorted old laptops and old workstations

- Laser printer (mono)

Other facilities

The Round Table

Possible our most important area; a place where people have a cup of tea, chat or do some work

Bathroom

Yes we have one of those. Wheel chair accessible.

Kitchen

Kettle, sink, cups a plenty, ...